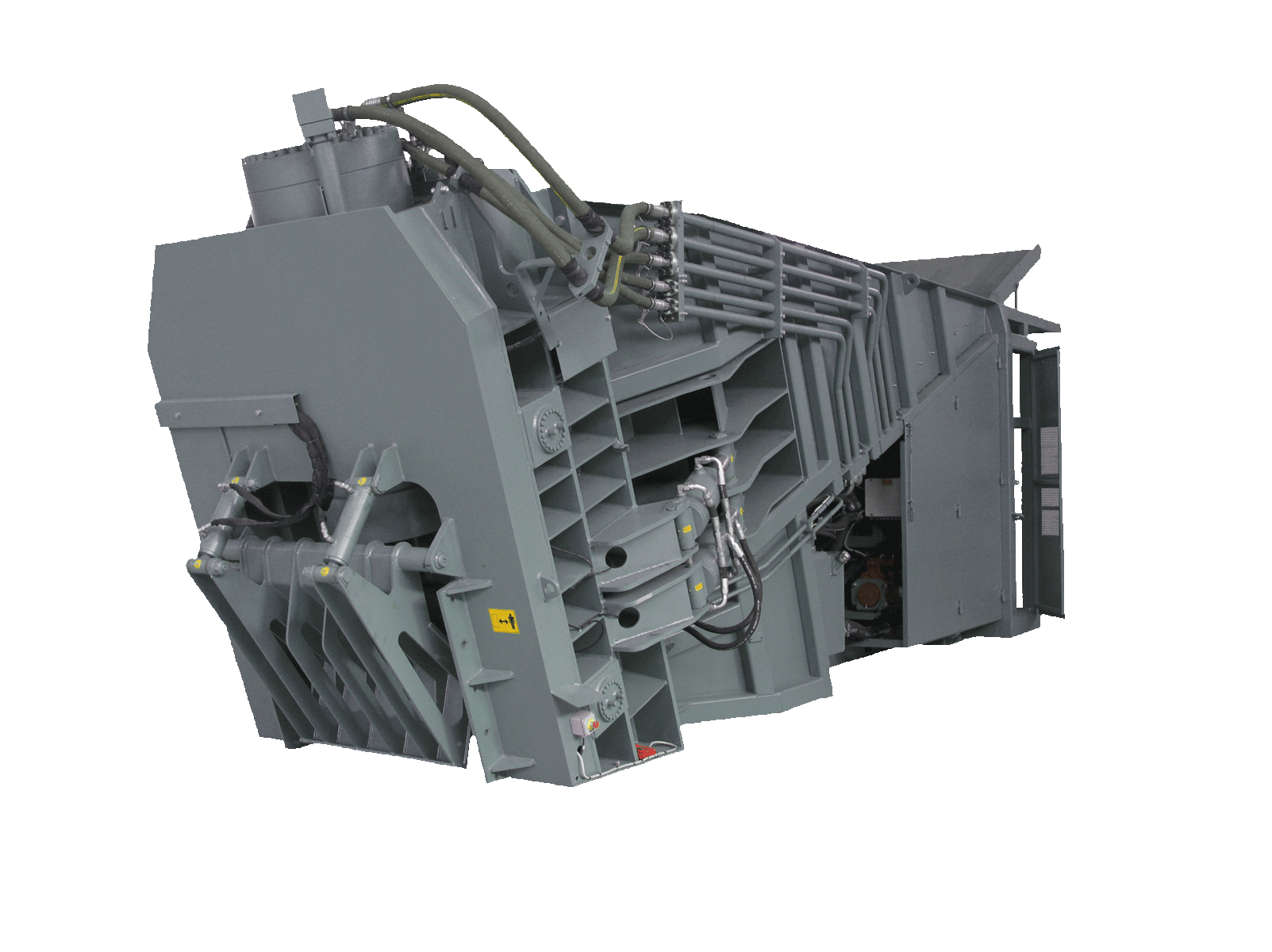

INCLINED SHEAR CI 3000

The “CI” series of inclined shears are ideal machines for industries and for recycling medium and heavy waste. Thanks to the large loading tank, it is the ideal machine for handling long materials such as beams, rails, pipes, sheet metal and scrap in general without length limitations.

The CI 3000 thanks to its compact layout, is installed at ground level on economical foundations thus facilitating maintenance thanks also to the side enclosures that can be opened completely.

The high productivity (up to 40 ton/h depending on the model) due to continuous charging and inclined plane, which thanks to gravity and vibrations of the plane itself, it brings the scrap to the cutting head where it is blocked by the lateral and vertical pressers for subsequent shearing, making it a fundamental equipment for industry and recycling.

The machine is driven by the latest generation of electric motors. The control of all movements and automatic cycles is entrusted to a PLC, which allows variations and corrections of presses and cutting lengths even during the working cycle. The choice of high quality hydraulic and electrical components make it an extremely robust and reliable equipment.

Designed for cutting medium heavy scrap

Continuous charging operation

Choice of cutting length

Extremely reliable

Easy to use

Powered by electric motors

Controlled by PLC

DATA SHEET

Total length 13500 mm

Overall width 2600 mm

Overall height 5000 mm

Casing length 10500 mm

Approximate weight 95.000 Kg

Structure S355 J2 G3 and WELDOX700

Antiwear casing HARDOX 400

Shear cylinders 1 or 2

Power tamper 1

Flipper 1+1

Flat moving cylinders 1

Cylinders cut size 1 or 2

Cutting

Sheared material 20 – 40 Ton/h

Electrical kW 320 (430 CV)

N° 4 Axial pistons-variable displacement pump max. working pressure 320 bar

N° 1 Double vane pump max. working pressure 320 bar

N° 2 Vane pump max. working pressure 320 bar

N° 2 Heat exchanger

Off-line system cooling/cleaning hydraulic oil

Automatic working cycle

Elettrical control system with PLC

Automatic greasing system

Remote control centralized interface

Oil pre-heating system

Remote control